Struggling to find a manufacturer you can trust? A bad partnership can sink your brand before it even starts. I'll show you exactly how to find the right one.

To find the best golf shirt manufacturer, focus on four key areas: fabric expertise, production quality, customization capabilities, and transparent communication. Look for a true partner who understands your brand’s vision and is equipped to help you scale. This guide breaks it all down for you.

What Makes a Quality Golf Shirt Manufacturer?

Choosing a manufacturer feels like a gamble. A bad choice means wasted money, low-quality products, and a damaged brand reputation before you even launch. I'll show you what truly matters.

A quality golf shirt manufacturer combines deep fabric expertise, meticulous craftsmanship, flexible customization options, and transparent communication. They act as a true partner, guiding you to create the best possible product and helping your brand grow from the start.

From my first days on a textile factory floor, I learned what separates the great manufacturers from the rest. It’s not just about sewing machines and thread. It’s about a deep commitment to excellence in every single step. For a new brand owner like you, finding a partner who shares that commitment is the most important decision you will make. Let’s break down the key qualities you must look for.

Why is Deep Fabric Knowledge Non-Negotiable?

All performance fabrics seem the same on a website. Using the wrong one leads to uncomfortable shirts that your customers will hate. A great manufacturer guides you to the perfect choice.

Deep fabric knowledge is non-negotiable because the material directly impacts shirt performance, comfort, and durability. An expert manufacturer ensures your apparel meets player expectations for breathability and feel, protecting your brand’s reputation from day one.

A manufacturer shouldn't just take your order; they should be a consultant. They should ask you about your brand. Who is your target customer? In what climate will they be playing golf? What is your target price point? The answers to these questions determine the best fabric choice. It’s never a one-size-fits-all solution. For instance, a lightweight jersey knit with high spandex content is great for hot, humid climates. A slightly heavier pique knit might feel more traditional and premium. An expert knows these differences. They can talk about the specific denier of the yarn or the benefits of a certain moisture-wicking chemical finish. They should be able to source specific materials for you, not just push their limited stock fabrics. This expertise is your first sign that you’re dealing with a professional who cares about your final product.

| Fabric Type | Best For | Key Properties |

|---|---|---|

| Polyester/Spandex Jersey | Hot and humid weather | Lightweight, maximum stretch, excellent moisture-wicking |

| Polyester Pique | A classic, premium feel | Textured, durable, good airflow, less clingy |

| Recycled Polyester | Eco-conscious brands | Sustainable, similar performance to virgin polyester |

| Nylon Blends | Durability and a silky feel | Very strong, smooth hand-feel, quick-drying |

How Do You Spot Superior Craftsmanship and Quality Control?

You probably can't visit the factory in person. How do you know their production quality isn't just based on edited photos? I'll teach you what to look for in their samples.

You spot superior craftsmanship by closely examining a physical sample. Check for clean, consistent stitching, perfectly aligned patterns, and smooth seams that don't chafe. A high-quality sample is the single best indicator of their overall production standards.

A sample shirt tells you everything you need to know. Never approve a bulk order without first holding a perfect sample in your hands. When it arrives, become a detective. Don't just look at it; analyze it. Turn it inside out. The inside of the garment reveals the true quality.

Your Sample Inspection Checklist

I always check these specific areas first.

- Stitching: Are the stitches per inch consistent? Look for tight, even stitching. On the inside, are the seams finished cleanly? A flatlock seam is a sign of quality, as it prevents chafing during a golf swing.

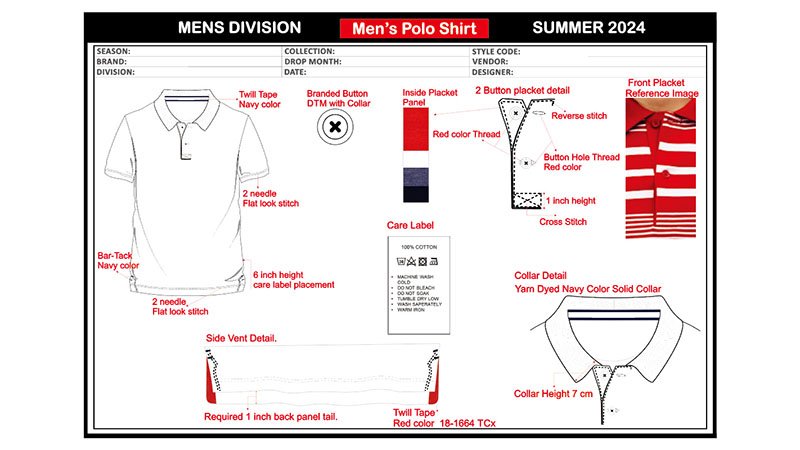

- Collars and Plackets: Does the collar lay flat without curling at the edges? A well-made shirt has a proper collar stand that gives it structure. The placket, where the buttons are, should be perfectly straight and reinforced.

- Buttons and Buttonholes: Are the buttonholes cleanly cut and stitched without any fraying threads? Are the buttons sewn on securely with a cross-stitch? These small details show they didn't cut corners.

Ask them about their quality control (QC) process. A good factory has checkpoints throughout production—not just at the end. They check the fabric when it arrives, they check the cut pieces, and they check the shirts during sewing. This prevents big mistakes and ensures consistency across your entire order.

Can They Bring Your Unique Brand Vision to Life?

Your brand has unique design ideas. Many factories, however, have rigid limitations that can stifle your creativity and brand identity. You need to find a flexible partner who works with you.

A quality manufacturer brings your vision to life by offering wide customization with manageable Minimum Order Quantities (MOQs). This includes custom fabric sourcing, diverse printing methods, and branded trims like labels and tags, allowing for true brand expression.

"Custom" should mean more than just putting your logo on their stock shirt. True customization allows you to build a product that is unique to your brand. For a new brand owner like Bobby, this is essential to stand out. Don't be afraid to ask detailed questions about their capabilities. Can they add a contrasting fabric to the inside of the collar? Can they do a custom zipper pull? These details are what customers notice. A key part of this conversation is the Minimum Order Quantity, or MOQ. Some factories have very high MOQs that are impossible for a new brand. A quality partner will offer reasonable MOQs, often per design or color, allowing you to launch with a varied collection without a massive upfront investment. They understand that your success will lead to larger orders in the future.

Key Areas for Customization

| Feature | What to Ask For | Sign of a Good Partner |

|---|---|---|

| Decoration | "What are the pros and cons of sublimation vs. embroidery for this design?" | They explain the options and recommend the best one for your fabric. |

| Finishing | "Can you create custom woven neck labels and branded hang tags?" | They have a process for this and can show you examples. |

| Fit | "Can we develop a custom fit block based on my specifications?" | They welcome custom patterns and can create prototypes. |

| MOQ | "What is your MOQ per design and color, not just the total order?" | They offer flexible and reasonable numbers for new brands. |

Is Your Manufacturer Just a Supplier or a True Partner?

Communication breakdowns can cause costly delays and mistakes. Vague answers and missed deadlines can sink your product launch before it even starts. You need to demand a partner, not just a supplier.

A true partner actively communicates, provides proactive updates, and uses their expertise to improve your product. They are invested in your success, not just in fulfilling an order. This collaborative relationship is built on trust, transparency, and shared goals.

This is the most important quality, and it’s the hardest to judge from a website. A supplier takes your order. A partner builds your brand with you. At FUWAY, I’ve always built my business on this principle. I once worked with a new brand that had a great design but chose a material that was too heavy. A simple supplier would have just made it. I called the client and explained the issue. We switched to a lighter, more breathable fabric that cost less and performed better. The client was thrilled, and the shirt became their bestseller. That’s partnership. Look for this in your interactions. Do they respond to your emails quickly and with clear answers? Are they transparent about timelines? Do they offer suggestions? A partner sees your success as their own. This relationship is your biggest asset for long-term growth.

| Mindset | The Supplier | The Partner |

|---|---|---|

| Communication | Reactive, answers only what is asked. | Proactive, provides updates and suggestions. |

| Problem Solving | Reports problems as they happen. | Anticipates problems and offers solutions. |

| Goal | To get the next purchase order. | To help you grow your brand. |

| Expertise | Keeps their knowledge to themselves. | Shares their expertise to improve your product. |

Conclusion

A quality manufacturer is your expert partner. They combine superior craftsmanship with transparent communication, helping you build a brand, not just a shirt. Your success becomes their success.

Printing Options for Golf Shirts

For printing, sublimation is ideal for vibrant, all-over designs, while embroidery offers a premium, classic look for logos. These choices directly impact comfort, durability, and style.

What Are the Best Printing Methods for My Designs?

You spent weeks perfecting a design, only to see it crack and fade after one wash. Don't let poor printing ruin your brand. Here's how to make your designs last.

Sublimation is best for complex, all-over patterns on polyester, as the ink becomes part of the fabric. Screen printing is a cost-effective choice for simpler, bold graphics on various materials. Embroidery provides a durable, high-end textured finish, perfect for crests and logos.

Your design and your brand's identity should guide your choice of printing method. I worked with a client who wanted a very loud, unique floral pattern that covered the entire shirt. Screen printing was out of the question because of the complexity and cost. We used sublimation on a lightweight polyester fabric, and the result was stunning. The colors were incredibly vibrant, you couldn't feel the print at all, and it became their signature piece. For another client with a classic, minimalist logo, nothing looked better than clean, tight embroidery on the chest. Each method has a purpose, so let's explore which is right for you.

Matching Method to Vision

The printing application is where your brand's visual identity comes to life. Each technique offers a different look, feel, and price point. Understanding them helps you make a strategic choice, not just a creative one.

Sublimation

This process uses heat to turn ink into a gas, which then fuses with polyester fibers. The design becomes part of the fabric itself. This means it will never crack, peel, or fade, and the printed area remains just as breathable as the rest of the shirt. It's the only way to achieve seamless, edge-to-edge patterns and photorealistic images. The one major limitation is that it only works on fabrics with a high polyester content, and it works best on light-colored materials.

Screen Printing

A classic and reliable method. Screen printing involves pushing ink through a mesh screen onto the fabric. It's very cost-effective for larger orders with simple designs (1-4 colors). The result is a bold, vibrant print that sits on top of the fabric. The downside is that it creates a non-breathable layer, making it less ideal for large graphics on a performance shirt. Quality can vary, and if not cured properly, the ink can crack over time.

Embroidery

This isn't printing, but it's a key decoration method. A machine stitches your design directly into the shirt. It adds texture and a high-perceived value, which is why it's a favorite for club crests and brand logos. It's extremely durable. However, it's not suitable for large designs, as it can become heavy and stiff, potentially puckering the lightweight fabric of a performance polo.

How Do I Choose the Right Combination for My Brand?

Feeling overwhelmed by all the options? You're probably worried about making a costly mistake. Let's simplify the decision so you can choose the perfect combination with total confidence.

First, define your brand identity: are you modern performance or classic heritage? Match that with your design complexity. This will naturally guide you to the right fabric and printing method. For example, a modern brand with a complex pattern needs a poly-blend with sublimation.

There is no single "best" combination. The right choice is the one that best serves your brand, your customer, and your designs. Think of it as a simple formula: Brand Identity + Design Style = Your Perfect Shirt. I always ask new brand owners to describe their ideal customer first. Is it a young, athletic golfer looking for an edge, or a seasoned player who values tradition? The answer to that question tells us almost everything we need to know. Once you have that clear vision, matching the technical specifications becomes easy. Let's put this into a practical framework.

A Framework for Your Decision

Making this decision is about balancing three things: your brand's story, your design's needs, and your budget. By thinking through each of these elements, you can avoid costly errors and create a product that truly resonates with your target audience. Use this table as a guide to find your path.

| Brand Profile | Target Customer | Common Design | Recommended Fabric | Recommended Decoration |

|---|---|---|---|---|

| The Modern Athlete | Competitive golfer, 25-40 | Bold, all-over patterns | 92% Polyester / 8% Spandex | Sublimation |

| The Classic Club | Traditional golfer, 40+ | Simple chest crest/logo | Pima Cotton or Heavy Poly Pique | Embroidery |

| The Weekend Warrior | Casual golfer, all ages | Funny or bold graphic | 100% Performance Polyester | Screen Printing or DTF |

| The Premium Minimalist | Style-conscious golfer | No logo, or a tiny icon | High-end Poly/Spandex blend | Subtle Embroidery |

If you're building a brand like "The Modern Athlete," your customer demands performance. They expect the shirt to stretch and breathe. A complex, eye-catching design executed with sublimation reinforces that modern, high-tech identity. In contrast, "The Classic Club" brand appeals to tradition. An embroidered crest on a substantial Pima cotton or textured pique polo feels premium and timeless. The key is alignment. When the fabric, the decoration, and the brand story all say the same thing, the customer gets it instantly.

Conclusion

Choosing the right fabric and printing is vital for your brand. Align your choices with your brand identity and customer needs to create a quality golf shirt they'll love.

Private Label & Customization Services Explained

Your brand looks just like every other, doesn't it? Putting your logo on stock apparel isn't enough to compete. I'll show you how true customization builds a brand that stands out.

Private label lets you put your brand on pre-designed apparel, while full customization allows you to create a unique product from scratch. Customization offers true differentiation by controlling fabric, fit, and details, building a stronger brand identity that connects with your specific audience.

I've worked with countless brands, from those just starting out to established names. I've seen first-hand how the path they choose—private label or full custom—defines their future. It's the most critical decision for a new founder. Let's explore what each path really means for you and your brand's journey.

What's the Real Difference Between Private Label and Full Customization?

Private label feels fast, but it severely limits your brand's potential. Full customization seems complex. I'll break down the core differences so you can choose the right path for long-term growth.

Private label is selecting a manufacturer's existing "blank" product and adding your logo. Full customization means designing every aspect yourself—fabric, fit, colors, and trim. Private label is about speed; full custom is about creating a truly unique brand identity.

When I was helping a new brand owner like you, Bobby, we faced this choice. He wanted to get his brand launched quickly. Private label was tempting because it's fast and the minimum order quantities (MOQs) are low. But I explained the risk. With private label, you're selling the exact same shirt as ten other brands, just with a different logo. There is no unique story to tell about the product itself. Full customization takes more effort upfront to develop your own unique pattern, fit, and material combination. It's a longer process, but the final product is 100% yours. This is how you build a real brand that customers love, not just a logo they recognize. Making that extra effort at the beginning is what separates successful brands from the ones that disappear after a season.

| Feature | Private Label | Full Customization |

|---|---|---|

| Product Design | Manufacturer's stock item | Your unique design |

| Fabric & Colors | Limited to stock options | Your specific choice |

| Fit & Sizing | Standard manufacturer sizing | Your custom specifications |

| MOQ | Usually lower | Generally higher |

| Time to Market | Faster | Slower (development time) |

| Brand Uniqueness | Low | High |

How Does Full Customization Create a Stronger Brand Identity?

Your brand gets lost in a sea of sameness. You need a product that screams your brand's story from the moment someone touches it. Here’s how custom details achieve exactly that.

Full customization allows you to embed your brand's DNA into the product itself. The choice of fabric texture, a unique fit, custom-branded buttons, or a signature placket style tells a story that a simple logo on a stock shirt cannot.

A strong brand identity is more than just a cool logo. It's an entire experience. Full customization lets you control that experience down to the smallest detail. I worked with a brand that wanted to feel modern and technical. We did more than just pick a fabric.

Beyond the Logo: The Power of Trim

We sourced custom zipper pulls with their brand mark. We used a special bonding technique on the shoulder seams to give it a clean, futuristic look. The neck tape inside the collar was printed with their slogan. These are the "discoverable" details that make a customer feel smart for choosing your brand. They create a premium perception and justify a higher price point.

Owning Your Fit and Feel

Most importantly, we developed a custom athletic fit for them. It wasn't the boxy, standard fit of a private label polo. It was tailored for their exact customer. When someone tries that shirt on, it just feels different. It feels like it was made for them. That feeling is what builds loyalty. Those small, intentional choices combine to tell your brand's unique story.

What Are the First Steps to Start a Custom Apparel Project?

You have a great idea for a golf shirt, but the process of making it seems overwhelming. Where do you even begin? I'll give you a clear, simple roadmap to get started today.

Start with a clear vision for your product and customer. Then, create a "tech pack"—a detailed blueprint with your design sketches, measurements, and material specs. This document is the key to getting accurate quotes and samples from manufacturers like me.

The journey from idea to finished product is more straightforward than you think. It all begins with a single document: the tech pack. This is the language of apparel manufacturing. Don't worry if you've never made one before; a good partner can help you. The goal is to get your ideas out of your head and onto paper in a structured way. Your tech pack should include the key details that make your product unique. The more detail you provide, the more accurate my quote will be, and the closer your first sample will be to your vision. Don't worry about it being perfect. A basic tech pack with sketches and notes is enough to start a productive conversation with a manufacturer. It shows you're serious and helps us give you real, actionable feedback.

| Key Component of a Tech Pack | Purpose |

|---|---|

| Flat Sketches | Visual blueprint of the design from all angles. |

| Measurement Chart | Defines the exact sizing and fit for each size. |

| Material Specs | Specifies fabric type, weight, and composition. |

| Color Pantones | Ensures precise and consistent color matching. |

| Trim Details | Specifies buttons, labels, zippers, and tags. |

Conclusion

Private label is a start, but full customization builds a legacy. By controlling every detail, you create a unique product that forges a true connection with your customers.

Quality Control and Industry Standards

You worry your manufacturer will cut corners, delivering a batch of flawed shirts. This costs you money and your brand's reputation before you even start. Let's fix that.

Ensure top quality by partnering with a manufacturer that has a documented QC process, like ISO 9001. You must also personally inspect samples—your physical proof—and demand in-production reports. Your active involvement is essential for success.

I learned about quality control on the factory floor, watching thousands of shirts get made. It's not a theory from a textbook. It is a relentless, step-by-step commitment to getting every single detail right. For a new brand owner like you, your most important job is finding a partner who shares that passion for excellence. A good manufacturer doesn't just make your product; they protect your brand. Let me show you what real quality control looks like and how you can verify it from anywhere in the world.

What Does a Real Factory Quality Control Process Look Like?

Manufacturers all promise "high quality," but what does that even mean? Without a clear process to check, you're just crossing your fingers and hoping for the best with your investment.

A real QC process involves multiple, specific checkpoints. It begins with inspecting raw materials (IQC), continues with checks during production (IPQC), and ends with a final inspection of every garment before shipping (FQC). It is a system, not a single event.

A quality manufacturer builds quality in at every stage. They don't just wait until the end to see if things went wrong. Think of it like building a house. You don’t wait until the roof is on to find out the foundation is cracked. From the moment your fabric arrives at my factory to the minute it's sealed in a box, we are checking it. We use a multi-stage process to catch problems early. This approach saves time and money, but most importantly, it guarantees the final product meets your exact specifications. It is the only way to produce consistent, high-quality apparel that a brand can be proud of. Every good factory has a version of this system.

| QC Stage | Name | What We Check |

|---|---|---|

| Step 1 | Incoming QC (IQC) | Fabric for flaws, color matching to Pantones, material weight (GSM). |

| Step 2 | In-Process QC (IPQC) | Stitching consistency, seam quality, label placement on the line. |

| Step 3 | Final QC (FQC) | Final measurements, cosmetic defects, functionality (buttons, zippers). |

Are Industry Certifications Like ISO 9001 Just Paperwork?

You see logos like "ISO 9001" on factory websites. It can feel like marketing fluff that doesn't actually guarantee your shirts will be good quality when they finally arrive.

No, ISO 9001 is not just paperwork. It is a globally recognized standard for a quality management system. It proves a factory has reliable, repeatable processes for ensuring quality, reducing errors, and consistently satisfying customer requirements.

I remember when my factory first went for ISO 9001 certification years ago. It was an enormous amount of work. We had to document every single process, from how we take a customer's order to how we handle a mistake on the production line. But it completely transformed our business. It forced us to be disciplined and consistent. For you, the brand owner, this certification is a powerful sign. It means that an outside, independent party has verified that the factory has a robust system in place. It’s not just me telling you we have good quality control; it’s an international standard that backs it up. It reduces your risk significantly because it shows the factory is committed to professional management and continuous improvement.

How Can You Personally Verify Quality Without Visiting the Factory?

You can't just fly across the world to watch over the production line. This distance can make you feel powerless, just hoping your manufacturer is doing what they promised.

You verify quality remotely by demanding and meticulously inspecting samples. Always get a pre-production sample and a top-of-production sample. Also, require photo and video updates from the factory floor. A transparent partner will provide this proof without hesitation.

Trust is important in a partnership, but you must always verify. The distance doesn't have to mean a lack of control. Modern technology makes it easy to stay involved. The most powerful tool you have is the sample. The pre-production sample is your contract. It is the physical version of your tech pack. Inspect it mercilessly. Check every stitch, every measurement. Once you approve it, no deviation is allowed. Then, once bulk production starts, you must ask for a "Top of Production" (TOP) sample. This is one of the first shirts off the real assembly line. It confirms the quality of your approved sample was successfully scaled to mass production. In addition, ask for updates. A good partner will be happy to send photos of the fabric being inspected or a video of the sewing line. If a factory hesitates to show you what’s going on, it's a huge red flag.

Conclusion

Don't just hope for quality; demand it. Use certifications, rigorous sample reviews, and clear communication to build a partnership that guarantees excellent products and protects your brand.

Cost, MOQ, and Lead Time Essentials

High MOQs drain your cash, long lead times delay your launch, and hidden costs can ruin your profits. This balancing act feels impossible for a new brand.

Focus on a flexible MOQ for your first order, even if the unit cost is slightly higher. Prioritize a clear, realistic production calendar over the absolute fastest timeline. This strategy protects your capital and reduces the risk of costly mistakes.

When I meet new brand founders, we always end up talking about these three things: Cost, MOQ, and Lead Time. They are not just numbers on a quote sheet. They are the core levers of your business. I've seen how a misunderstanding of one can derail an entire launch. But if you learn how they influence each other, you can make smart decisions that will set your brand up for success from day one. It's the most critical lesson in this business.

What Really Drives the Cost of Your Custom Golf Shirts?

You received a quote that was much higher than you expected. Now you are wondering if your dream shirt is even affordable, or if the factory is overcharging you.

The main cost drivers are your choice of fabric, the complexity of your design, and your order quantity. Premium performance fabrics and detailed prints or embroidery will always cost more than basic materials and simple logos. Bigger orders reduce the per-unit cost.

The final price of a garment is a sum of its parts. It's simple math, but you need to know what parts cost the most. When I work with a new brand like yours, I always start by explaining where the money goes. It helps you decide where to invest and where you can potentially save without sacrificing quality.

Fabric is Your Biggest Expense

The single biggest factor in your shirt's cost is the fabric. A high-performance, moisture-wicking blend of recycled polyester and spandex will cost significantly more than a standard polyester pique. This is often the best place to invest your budget because your customers will immediately feel the difference in quality and comfort.

Complexity and Trim Add Up

Every detail has a price. A shirt with a simple embroidered logo on the chest is cheaper to produce than a shirt with a vibrant, all-over sublimation print. Custom-branded buttons, unique zipper pulls, and specialty neck tape all add small costs that accumulate. By understanding this, you can choose details that give you the most brand impact for your budget.

| Cost Factor | Lower Cost Option | Higher Cost Option |

|---|---|---|

| Fabric | Standard Polyester Pique | Recycled Poly/Spandex Jersey |

| Decoration | Single Color Screen Print | All-Over Dye Sublimation |

| Trim | Stock Plastic Buttons | Custom Engraved Buttons |

| Quantity | 1000+ units | 100 units |

Why Do Manufacturers Have Minimum Order Quantities (MOQs)?

You only want to order 50 shirts to test your idea. But every factory is asking for a minimum of 300 or 500 pieces, forcing you into a huge upfront investment.

MOQs exist because factories have their own minimums for buying fabric and high setup costs for production lines. Running a very small batch is inefficient for the factory. However, a good partner will work with you to find a flexible solution.

I understand the frustration with MOQs. It feels like a barrier designed to keep small brands out. But let me explain the view from the factory floor. It's not about blocking you; it's about the physical reality of manufacturing.

The Fabric Mill's Rule

The primary reason for MOQs is fabric. Fabric mills produce material in huge batches. They will not produce just 100 meters of a custom color for us. We have to buy a full roll, which is often enough fabric for 500-1000 shirts. If your order is only 100 shirts, we are left with a lot of unused, custom-colored fabric.

Production Line Efficiency

Setting up a production line takes hours. We have to load the patterns into the cutting machines, configure every sewing station, and set up the printing equipment. All of this setup costs the same whether we are making 50 shirts or 500 shirts. Spreading that cost across a larger order makes the per-shirt cost reasonable. A good manufacturing partner will be transparent about this and try to find a solution, like offering a higher price for a smaller test run.

How Can You Realistically Manage Production Lead Times?

You told your followers a launch date for your new collection. But your manufacturer just quoted a 90-day lead time, and now you are panicking about missing your own deadline.

A standard production lead time is 60-90 days after you approve the final sample. This includes fabric sourcing, cutting, sewing, and quality control. You must plan for this by starting your design process at least 4-5 months before your target launch date.

The term "lead time" is one of the most misunderstood in this industry. It does not start the day you first contact a manufacturer. Knowing the true timeline is critical for planning a successful launch without last-minute stress.

The Clock Starts After Sample Approval

The lead time you are quoted is for bulk production only. It does not include the time it takes to develop and perfect your samples. The back-and-forth process of creating your tech pack, making the first sample, and potentially making revisions can take anywhere from two to six weeks. Only when you hold the perfect pre-production sample in your hands and say "Go!" does the bulk production clock actually start.

Plan for the Unexpected

A realistic timeline also includes buffer time. Production can be delayed by things outside of anyone's control, like national holidays, shipping port congestion, or a batch of fabric failing our initial quality check. A smart brand founder builds an extra 2-3 weeks into their timeline as a safety net.

| Production Stage | Typical Duration |

|---|---|

| Design & Tech Pack Creation | 1-2 Weeks |

| Sample Development & Revisions | 2-6 Weeks |

| --- Final Sample Approved --- | (Lead Time Clock Starts) |

| Fabric Sourcing & Inspection | 3-4 Weeks |

| Cutting, Printing/Embroidery, Sewing | 3-4 Weeks |

| Final QC, Packing & Shipping Prep | 1-2 Weeks |

Conclusion

Mastering cost, MOQ, and lead time is key. Balance them to protect your cash, manage risk, and build a sustainable brand that lasts for years to come.

How to Select the Best Golf Shirt Supplier?

You're lost in a sea of generic factory websites, all promising "high quality." Choosing the wrong one is a mistake that could cost you your entire brand before it even starts.

Look beyond just the price. The best supplier is a partner who communicates clearly, has deep expertise specifically in golf apparel, and is genuinely invested in helping your new brand grow. Their success should be tied to your success.

I've been on both sides of this handshake. I've been the factory manager, and I've been the advisor to new brand founders like you. The single biggest mistake I see is choosing a supplier based on who is cheapest. A good partner is an investment in your brand's future. A cheap vendor is an expense that will cost you more in the long run through mistakes, delays, and poor quality. Let's break down how to tell the difference.

How Can You Judge a Supplier's Communication Skills Early On?

You send a detailed email with specific questions and get a vague, one-line reply. This lack of clarity creates doubt and stress. How can you trust them with your product?

Pay attention to their first few emails. A great partner will respond within a reasonable time, answer every one of your questions directly, and, most importantly, ask clarifying questions of their own. Their questions prove they are engaged and experienced.

Communication is the foundation of a successful manufacturing relationship. A misunderstanding can lead to a sample that's completely wrong, wasting weeks of your time and hundreds of dollars. I tell new brand owners to treat the first few interactions like an interview. You are not just buying a product; you are hiring a team.

The Quality of Their Questions

A factory that just says "send tech pack" is a red flag. A true partner wants to understand your vision. They will ask things like: "Who is your target customer?", "What kind of fit are you aiming for—athletic or relaxed?", "What's the main feeling you want this shirt to convey—premium, technical, or classic?". These questions show they are thinking about the final product, not just the production process. They are using their experience to help you avoid common mistakes.

Clarity and Transparency

Look for someone who writes in clear, simple language. If their answers are confusing or they avoid answering a question directly, it's a sign of problems to come. A good partner is also transparent about their process and their limitations. If they can't do something, they should tell you why and suggest an alternative.

| Communication Red Flags | Communication Green Flags |

|---|---|

| One-line replies | Detailed, point-by-point answers |

| Takes a week to respond | Responds within 24-48 business hours |

| Ignores your specific questions | Asks clarifying questions about your vision |

| Says "yes" to everything | Is honest about what is and isn't possible |

| Vague pricing ("it depends") | Provides a preliminary quote with clear conditions |

What Separates a Golf Apparel Specialist from a General Factory?

Your sample arrives and it feels all wrong. The fabric is generic, and the fit is boxy. The factory simply didn't understand the unique needs of a golfer.

A golf apparel specialist lives and breathes performance fabrics, athletic swing-friendly fits, and the small functional details that golfers demand. They are advisors who can improve your product, not just order-takers who can sew a generic polo.

Any factory can make a polo shirt. But very few can make a true golf polo. The difference is in the details, and those details are everything in this competitive market. I started in this business because I love golf, and I bring that passion to the factory floor. When you talk to a supplier, you need to find out if they share that specific knowledge.

Expertise in Performance Materials

A specialist will be able to discuss the pros and cons of different fabric blends. They will know about moisture-wicking properties, the importance of UPF sun protection, anti-odor treatments, and the perfect percentage of spandex for a 4-way stretch that doesn't feel heavy. They will have a library of performance fabrics ready for you to choose from. A general t-shirt factory will likely just offer you standard polyester pique and call it a day.

Understanding the Golfer's Fit

A golf shirt is not a fashion shirt. It requires a specific pattern. You need more room and mobility across the shoulders and upper back to allow for a full, unrestricted swing. A specialist manufacturer knows this. They have proven "blocks" or base patterns designed for golfers that we can then customize to your brand's exact specifications. This expertise saves you months of trial and error in the sampling phase.

Is Your Supplier a Vendor or a True Partner?

You feel like just another order number. The factory only cares about getting your deposit and shipping the goods. They show no interest in whether your brand actually succeeds.

A vendor is transactional; they just want to complete the order. A partner is relational; they want to build a long-term business with you. A partner offers advice, shows flexibility, and celebrates your successes because they know your growth means their growth.

This is the most important distinction of all. In my years of running FUWAY, I have seen that the most successful brands are the ones who build true partnerships with their suppliers. A vendor will give you the lowest price, but a partner will give you the most value.

Thinking Beyond the First Order

When I first talk to a new founder, I ask them about their vision for their second and third collections. I want to know their long-term goals. This helps me recommend materials and designs that can evolve with them. A partner is thinking about how to make you successful for years to come. A vendor is only thinking about how to get the current purchase order signed. They are proactive, suggesting new fabric technologies or ways to reduce costs on your next run.

Flexibility and Problem-Solving

What happens when a problem arises? Because in manufacturing, problems always arise. A vendor might simply blame you or point to the fine print in the contract. A partner rolls up their sleeves and works with you to find a solution. When I see a promising new brand founder like Bobby, I am often willing to be more flexible on the first order's MOQ. I see it as an investment in a future relationship. That initial flexibility is a powerful sign that you've found a partner, not just a vendor.

Conclusion

If you’re launching a golf apparel brand or looking to upgrade your supplier, focusing on the right manufacturer is critical for your long-term success. Here are the key points to remember when choosing the best golf shirt manufacturer:

- Choose Industry Experts: Work with manufacturers who specialize in golf shirts and understand performance fabrics and functional construction.

- Prioritize True Customization: Seek partners who offer full customization—unique materials, fit, trims, and decoration options—not just logo placement.

- Insist on Quality Control: Always review physical samples and make sure there is a multi-stage QC process in place for consistent, reliable quality.

- Value Clear Communication: Select suppliers who respond quickly, ask insightful questions, and provide helpful guidance, rather than just taking orders.

- Balance Cost & MOQ: Recognize that a lower minimum order or more customization may increase per-unit costs; plan production timelines and budgets accordingly.

- Private Label vs. Full Customization: Private label is fast but lacks uniqueness; full customization strengthens your brand’s identity and market position.

- Decoration Methods Matter: Use sublimation for complex, all-over designs, embroidery for premium logos, and screen printing for simple graphic elements.

In summary:

Partner with manufacturers who offer expertise, transparency, and customization to help your golf apparel brand stand out and grow sustainably.