Wondering how a simple sketch becomes a high-performance golf shirt? This complex process can seem overwhelming, leaving your brand ideas stuck on paper. Let's break down the manufacturing journey.

Golf shirts are made through a multi-stage process: design and tech pack creation, performance fabric selection, precise automated cutting, and skilled sewing. Quality control checks at each step ensure the final product meets high standards for comfort, fit, and durability on the course.

On paper, the steps sound simple. But I've spent years on the factory floor, and I can tell you the real magic is in the details. Each stage, from the first sketch to the final stitch, has its own challenges. Understanding these details is key to creating a truly great golf shirt. Let's dive into the process.

What are the key steps in designing a golf shirt?

Have a great idea for a golf shirt but don't know where to start? Without a clear plan, your vision can get lost in translation with the factory, resulting in samples that miss the mark.

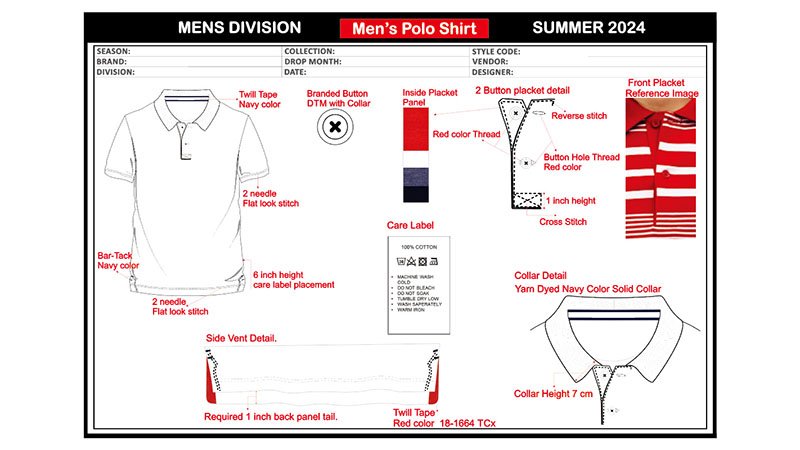

The key steps are concept creation, technical sketching, and building a detailed "tech pack." This document includes all specifications like measurements, fabric, colors, and logo placement, acting as the blueprint for manufacturing and ensuring your vision is produced accurately.

I remember working with a new brand owner, Bobby, who sent me a single JPEG image of his design. He was a great marketer but new to apparel production. When I asked for his tech pack, he wasn't sure what it was. We worked together to build one from scratch, detailing everything from the placket's stiffness to the exact Pantone color for his logo. This upfront work prevented so many potential errors. It showed him that a good design is more than just a picture; it's a complete set of instructions that leaves nothing to chance. A comprehensive tech pack is the most important communication tool you have with your manufacturer.

Building Your Blueprint: The Tech Pack

Think of the tech pack as the architect's blueprint for your golf shirt. It's the single source of truth for the entire production team. Without it, you're just guessing.

- Flat Sketches: These are technical drawings of your shirt from the front, back, and sometimes a side view. They show all the seam details, collars, and plackets.

- Bill of Materials (BOM): This list details every single physical component of the shirt. It includes the main body fabric, thread, buttons, care labels, and any other trims.

- Graded Spec Sheet: This chart lists the exact measurements for every size you plan to produce (S, M, L, XL, etc.). It ensures a consistent fit across your entire size range.

- Construction Details: This section provides specific instructions for the sewing team, like the type of stitch to use on the hem or how to attach the collar.

How is fabric selected for golf shirts?

Your customers expect to stay cool and dry on the course. Choosing the wrong fabric leads to uncomfortable shirts that don't perform, damaging your brand's reputation with serious golfers.

Fabric for golf shirts is selected based on performance characteristics. Polyester and spandex blends are top choices for their moisture-wicking and four-way stretch. The goal is to balance breathability, UV protection, durability, and comfort to meet the demands of the modern golfer.

Early in my career, a client insisted on using 100% cotton for a line of "classic" golf polos. I tried to explain the performance drawbacks, but he was set on the traditional feel. After the first production run, his customer reviews were terrible. They mentioned the shirts felt heavy with sweat and took forever to dry. He switched to a polyester-spandex blend for his next order, and the feedback improved immediately. This taught me a critical lesson: in modern golf apparel, performance is not optional. The fabric you choose is the foundation of your shirt's function and its success in the market.

Matching Fabric to Function

The right material does more than just look good; it has to work hard. Golfers need a shirt that moves with them, manages sweat, and feels good against the skin for hours.

| Feature | Why It Matters | Common Materials Used |

|---|---|---|

| Moisture-Wicking | Pulls sweat away from the skin to keep the player dry. | Polyester, Microfiber Blends |

| Breathability | Allows air to circulate, preventing overheating. | Performance Knits, Mesh Panels |

| Stretch | Provides freedom of movement for the golf swing. | Spandex (Elastane) Blends |

| UV Protection | Shields the skin from harmful sun rays (UPF 30+). | Specially treated synthetics |

What is the cutting and sewing process like?

Turning a roll of fabric into a perfectly shaped shirt is a precise task. Any mistakes in cutting or sewing can lead to inconsistent sizing and a poor-quality final product.

The process starts with laying out large sheets of fabric. A computer-guided machine then cuts the pattern pieces with extreme precision. These pieces are bundled by size and sent to sewing lines where skilled operators assemble each shirt step-by-step.

Walking onto a production floor for the first time is an amazing experience. You see this perfectly synchronized system. In one area, a massive cutting machine slices through 100 layers of fabric at once, faster and more accurately than any human could. A few feet away, you have rows of sewers, each an expert at a single task—one attaches collars, another sets sleeves, and another stitches the final hem. I love watching the organized chaos as piles of flat fabric pieces are transformed into finished garments. This division of labor is what allows us to produce thousands of identical, high-quality shirts efficiently.

From Fabric Rolls to Finished Garments

The journey from a flat piece of cloth to a 3D shirt is a highly organized operation.

- Spreading: The fabric is unrolled onto long cutting tables in many layers. Great care is taken to ensure the fabric is smooth and free of tension, which could distort the final pieces.

- Automated Cutting: The approved digital patterns are loaded into a computer. This computer controls a high-speed cutting tool that follows the pattern lines exactly. This automation guarantees that every piece for a size Medium shirt, for example, is identical.

- Bundling: After cutting, the pieces (front, back, sleeves, collar) are grouped into bundles for a specific number of shirts, usually by size and color. This keeps everything organized for the sewers.

- Assembly Line Sewing: The bundles move down a line of sewing stations. Each operator performs a specific step, passing the partially completed shirt to the next person. This method is fast and ensures consistent quality for each seam.

How is quality control maintained throughout production?

You worry that your finished shirts will have flaws like loose threads or crooked logos. Inconsistent quality can quickly destroy customer trust and lead to costly returns and negative reviews.

Quality control (QC) is a continuous process, not a final step. We inspect raw materials on arrival, check pieces after cutting, monitor the sewing lines, and perform a final 100% inspection of every finished garment before it is packed and shipped.

I’ll never forget an early order where we found a small stitching defect on the collar of one shirt during the final inspection. We decided to check the whole batch of 1,000 shirts again, piece by piece. We found the same issue on about 50 of them, all sewn by the same operator whose machine tension was slightly off that morning. We fixed every single one. It taught me that waiting until the end is too late. Now, we have QC checkpoints throughout the process. This "inline" inspection catches small problems before they become big ones, saving time and ensuring my clients get the perfection they expect.

A Multi-Stage Inspection System

A great product is the result of constant vigilance. We build quality into the shirt at every stage rather than just trying to inspect it at the end.

- Pre-Production Checks: Before we even start, we check all fabrics, buttons, and threads to make sure they match the tech pack and are free of defects.

- Inline Audits: During sewing, our QC team walks the production lines. They pull random shirts and check them against the approved sample. This helps us spot any issues with a specific machine or operator immediately.

- End-of-Line Inspection: As shirts come off the assembly line, they go through another check for any visible defects before they are sent for finishing touches like buttoning and pressing.

- Final AQL Inspection: Before packing, every single shirt undergoes a final, thorough inspection. We check measurements, stitching, logo placement, and overall cleanliness. This ensures that only A-grade products are shipped out.

What role does technology play in making golf shirts?

You want your golf apparel to be modern and innovative, but you're unsure how technology impacts manufacturing. Falling behind on tech can mean lower quality, slower production, and less competitive products.

Technology is crucial in modern golf shirt manufacturing. It's used for precise pattern making (CAD), automated fabric cutting, advanced sewing machines for durable seams, and digital printing techniques like sublimation for vibrant, long-lasting designs. It improves quality, speed, and design possibilities.

When I started in this industry, everything was done by hand. We made patterns from cardboard and cut fabric with giant shears. It was slow, and it was hard to get perfect consistency. Today, technology has changed everything. I remember the first time we got a sublimation printer. The ability to print a full-color, complex design directly into the fabric was a game-changer. Brands could now create amazing, photo-realistic designs that wouldn't crack or peel. Adopting new technologies like this is not just about being faster; it's about giving brand owners like Bobby the tools to be more creative and deliver a superior product to their customers.

Innovations Driving the Industry

Technology touches every part of the shirt-making process, leading to better, more consistent, and more creative apparel.

- Computer-Aided Design (CAD): Software allows us to create, modify, and grade patterns with perfect accuracy. We can even create 3D digital samples to check the fit before cutting any fabric.

- Automated Cutting Machines: These machines use the CAD patterns to cut hundreds of layers of fabric at once with laser precision, reducing waste and ensuring every piece is identical.

- Sublimation Printing: This digital printing process transfers dye into the fabric using heat. It allows for unlimited colors and complex designs that are breathable and permanent.

- Advanced Sewing Machines: Modern industrial sewing machines are programmed for specific tasks, like creating perfectly reinforced buttonholes or strong, flatlock seams that prevent chafing, enhancing both durability and comfort.

FAQ

What is a typical Minimum Order Quantity (MOQ) for custom golf shirts?

For most custom designs, our MOQ starts at around 500 pieces per style and color. This number allows us to efficiently source custom-dyed fabrics and set up the production line. We understand this can be a hurdle for new brands, so we always try to be flexible where possible.

How long does it take to produce a custom golf shirt order?

A general timeline is about 6-8 weeks from the moment you approve the final sample. This breaks down into roughly 2-3 weeks for creating and shipping the initial sample, and then 4-6 weeks for bulk production. Shipping time will vary depending on your location and chosen method (air or sea).

What are the best methods for applying a logo to a golf shirt?

The two most popular methods are embroidery and heat transfer. Embroidery offers a classic, premium look with a durable, textured feel. Heat transfer (or screen printing) is great for complex, multi-color logos and creates a smooth, modern finish that integrates with the performance fabric. The best choice depends on your logo and brand aesthetic.

Are there sustainable or eco-friendly options for golf shirt fabrics?

Absolutely. We are seeing a huge demand for sustainable materials. The most common option is recycled polyester (rPET), which is made from post-consumer plastic bottles. It offers the same moisture-wicking and performance benefits as virgin polyester while reducing environmental impact.

Conclusion

Creating a high-quality golf shirt involves a detailed process of design, material selection, and precise manufacturing. Understanding each step helps you build apparel that truly performs on and off the course.