Choosing custom apparel feels overwhelming. You want your team to look amazing, but you fear making a costly mistake. Don't let uncertainty lead to a poor investment.

To choose the best custom golf apparel, focus on four key areas: performance fabric, comfortable fit, smart customization, and a reliable manufacturing partner. Prioritize moisture-wicking polyester blends for comfort and choose a supplier who understands your brand's vision and can deliver consistent quality.

I've spent my life in the apparel industry, starting in a small textile factory and building a business that helps brands like yours. I've seen what works and what doesn't. Making the right choice isn't just about picking a color. It's about building your team's identity and giving them the confidence to play their best. Let me walk you through the details that separate good apparel from great apparel.

What Fabric Should You Prioritize for Performance and Comfort?

Playing in the wrong gear is miserable. Sweaty and uncomfortable shirts can ruin a game. You must choose fabrics that help your players, not hold them back.

Always prioritize synthetic fabrics like polyester and elastane (spandex). These materials are excellent at moisture-wicking, which pulls sweat away from the skin. They are also breathable and flexible, keeping your team cool, dry, and comfortable for the entire 18 holes.

I remember my early days working directly with textiles. I learned quickly that not all fabrics are created equal. Cotton, for example, feels soft at first. But once you start sweating, it becomes heavy and cold. It holds moisture instead of releasing it. That experience taught me why performance fabrics are non-negotiable for golf. The right material can genuinely impact a player's focus and endurance. It’s the foundation of any quality golf garment. You are not just buying a shirt; you are investing in performance.

Key Fabric Characteristics

The best golf apparel fabrics have a few things in common. They need to manage moisture to keep players dry. They need to stretch to allow a full range of motion in the golf swing. And they need to be durable to withstand many rounds and washes. Some even offer UV protection, which is a huge bonus for long days on the course.

Comparing Common Golf Apparel Fabrics

Let's break down the most common options. Understanding the pros and cons of each will help you make an informed decision for your team.

| Fabric | Moisture-Wicking | Breathability | Stretch | Best For |

|---|---|---|---|---|

| Polyester | Excellent | Very Good | Good | All-around performance polos and outerwear |

| Spandex/Elastane | Good | Good | Excellent | Being blended with polyester for flexibility |

| Nylon | Very Good | Good | Very Good | Durable outerwear and bottoms |

| Cotton | Poor | Good | Poor | Casual wear off the course, not for play |

Most top-tier golf shirts are a blend, typically 88-92% polyester and 8-12% spandex. This combination gives you the perfect mix of moisture management, durability, and four-way stretch. It’s the formula I recommend to almost every brand I work with.

How Do You Balance Customization with Your Budget?

You have a great vision for your team's apparel, but the budget is tight. You worry that getting a unique, professional look will be too expensive. It doesn’t have to be.

Balance your budget by choosing the right customization method for your design and order size. For simple logos on any quantity, embroidery offers a premium feel. For complex, all-over designs, sublimation provides vibrant colors without extra cost per color, making it a great value.

I once had a client, a new brand owner just like you, who came to me with a beautiful, intricate design full of colors. He thought his only option was screen printing, and the cost for so many colors was terrifying him. I introduced him to dye-sublimation. With sublimation, the number of colors doesn't impact the price. We were able to create his vibrant, full-coverage design within his budget. His brand launched with apparel that truly stood out. Matching the right technique to the design is key to managing costs effectively.

Understanding Customization Methods

The method you choose affects the look, feel, and price of your final product. Each one has its place. Knowing the difference is crucial for making a smart financial and aesthetic decision. Don’t just pick the cheapest option; pick the one that best serves your design and your brand's image.

Cost vs. Impact Analysis

Here is a simple breakdown to help you compare the most common methods.

| Method | Best For | Durability | Feel | Cost Structure |

|---|---|---|---|---|

| Embroidery | Logos, text, premium look | Excellent | Stitched, slightly raised | Based on stitch count |

| Screen Printing | Simple graphics (1-4 colors) | Good | A thin layer of ink on top | Cost per color, cheaper in bulk |

| Heat Transfer | Detailed logos, small orders | Moderate | Smooth film on the surface | Good for small, complex graphics |

| Sublimation | All-over, complex designs | Excellent | No feel, part of the fabric | Flat price, not based on color count |

Think about your needs. If you just need a club crest on the chest, embroidery is a classic, durable choice. If you want a bold, unique pattern that covers the entire shirt, sublimation is your best bet financially and for performance, as it doesn't block the fabric's breathability.

Why is Choosing the Right Manufacturer So Critical?

You might find a supplier offering a very low price. This seems great, but are they reliable? A bad manufacturing partner can cause delays, deliver poor quality, and damage your brand's reputation.

A good manufacturer is a true partner. They guarantee consistent quality, meet your deadlines, and provide expert guidance. Their reliability protects your investment and reputation, giving you the confidence to grow your brand without worrying about production issues. It's the most important relationship you'll build.

When I started FUWAY, my goal wasn't just to produce clothes. It was to build relationships. I've seen new brand owners get burned by factories that promise the world but disappear when there is a problem. A true partner communicates openly, helps you solve problems, and is invested in your success. They understand that if you succeed, they succeed. This partnership approach is everything. It's the difference between a one-time order and a long-term, successful brand. We don't just make your apparel; we help you build your business.

Qualities of a Great Manufacturing Partner

Finding the right partner is about looking for specific green flags. These are signs that a manufacturer is professional, experienced, and trustworthy. They are experts in their field and are set up to help brands like yours. Pay close attention to how they communicate and what they are willing to show you.

Green Flags vs. Red Flags

Here’s a quick guide to help you spot a great partner from a risky one.

| Green Flags (Signs of a Good Partner) ✅ | Red Flags (Warning Signs) ❌ |

|---|---|

| Clear, prompt communication | Vague answers and slow replies |

| Provides physical samples for approval | Refuses or charges excessively for samples |

| Has experience with golf apparel specifically | Is a generalist with no specialty |

| Offers low MOQs for new brands | Demands very high minimum orders |

| Transparent about their process and timeline | Unclear about production steps or deadlines |

| Has positive reviews and case studies | No verifiable track record or references |

Your manufacturer is an extension of your team. Do your research, ask tough questions, and never settle for a partner who doesn't seem fully committed to your vision.

What Are the Key Steps in the Design and Ordering Process?

The path from an idea to a finished product can seem complex. You might worry about missing a critical step, leading to a final order that isn't what you envisioned.

The process has clear stages: design mock-up, material selection, sample approval, and bulk production. The most vital step is approving a physical sample. This ensures the fit, colors, and quality meet your standards before you commit to the full order. Never skip the sample.

I guide clients through this exact process every day. It's designed to eliminate surprises. Think of it as building a house. You wouldn't start construction without a detailed blueprint, and you shouldn't start production without a perfect sample. I always tell new brand owners to be picky during the sampling stage. Test it, wear it, wash it. This is your chance to get everything right. A good manufacturer will welcome this feedback because we want you to be 100% happy with the final product.

From Idea to Final Product

The journey is a collaboration between you and your manufacturer. Each step builds upon the last, ensuring a smooth and predictable outcome.

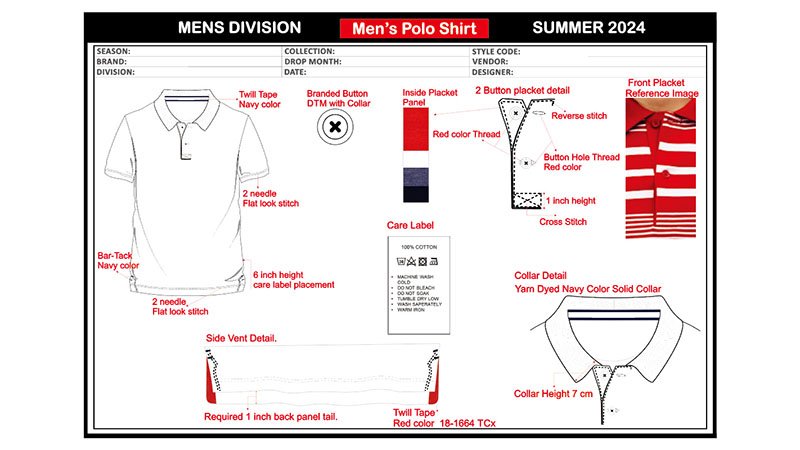

- Consultation and Design: It all starts with your vision. You share your ideas, logos, and color schemes. Your manufacturing partner will then create a digital mock-up or "tech pack," which is the technical blueprint for your garment.

- Fabric and Trim Sourcing: Based on the design, the manufacturer sources the perfect fabric and trims (like buttons and zippers). You will get to confirm that these materials meet your performance and quality standards.

- Prototyping and Sampling: This is where your design comes to life. A physical sample is created. This is your most important quality checkpoint. You get to feel the fabric, check the fit, and see the colors in person.

- Feedback and Revisions: You provide feedback on the sample. If any changes are needed, whether to the fit or a color, this is the time to make them. The manufacturer will revise the sample until you give your final approval.

- Bulk Production: Once you approve the final sample, mass production begins. Your manufacturing partner will oversee the entire process, implementing quality control checks along the way to ensure every piece matches the approved prototype.

- Final Inspection and Shipping: A final quality check is performed before the apparel is packaged and shipped to you. A good partner will also handle the logistics, making sure your order arrives safely and on time.

Conclusion

Choosing the right custom golf apparel is simple when you focus on what matters. Prioritize performance fabrics, match customization to your budget, and most importantly, select a reliable manufacturing partner.