Golfers hate stuffy polos that trap heat. This discomfort can hurt their game and your brand. The secret to supreme comfort lies in the right fabric selection.

To improve breathability, focus on three key areas. Use performance blends with Phase Change Materials for temperature control. Incorporate laser-cut ventilation for direct airflow. And explore smart fabrics that provide real-time data for even better designs. These choices make all the difference.

I've spent years in textile factories, touching and testing thousands of fabrics. I learned that just saying "polyester" isn't enough. The real magic is in the details—the specific blends, the construction, and even the technology woven into the threads. Many brands overlook these details, but they are what separate a good polo from a great one. If you want to give your customers the best, you need to understand these advanced techniques. Let’s break down exactly what you should be looking for.

How can performance blends create dynamic temperature control?

Your polos feel good in one temperature, but not another? This inconsistency frustrates golfers. Advanced blends with PCMs adapt dynamically, providing comfort no matter how the weather changes.

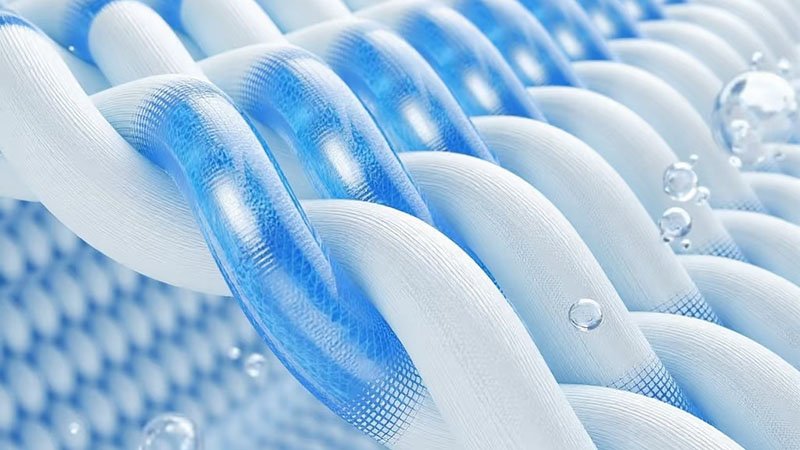

Performance blends with Phase Change Materials (PCMs) create dynamic control by actively absorbing, storing, and releasing heat. As you warm up, the PCMs absorb heat. When you cool down, they release it back, keeping your body's microclimate stable and comfortable throughout the round.

When I first started in this business, "performance fabric" just meant moisture-wicking polyester. But technology has come a long way. Let's look closer at how these modern blends work.

What are Phase Change Materials (PCMs)?

Think of PCMs as tiny, smart batteries for temperature. They are micro-encapsulated materials mixed into the fabric's yarn. These capsules absorb your body heat when you're getting hot, changing from a solid to a liquid inside their shell. This process cools you down. Then, if the clouds roll in and you start to feel a chill, they release that stored heat, changing back to a solid and warming you up. It’s a proactive system, not a reactive one.

Why They Outperform Standard Blends

A standard polyester polo wicks sweat away. That's good, but it's a passive function. A PCM-infused polo actively manages the temperature before you even start sweating heavily. This is a huge selling point for any golf apparel brand. For a brand owner like yourself, offering a polo with this "smart" thermal regulation elevates you above the competition. It's a tangible benefit golfers can feel from the first tee to the last.

| Feature | Standard Poly-Spandex | PCM-Infused Blend |

|---|---|---|

| Moisture Wicking | Good | Excellent |

| Temperature Control | Passive (relies on sweat) | Active & Dynamic |

| All-Day Comfort | Variable | Consistent |

| Brand Appeal | Standard | Premium / Tech-Forward |

Can you add ventilation without making the shirt look weak?

Want to add ventilation but fear it will look cheap or tear easily? Poorly placed vents can compromise the polo’s structure. Laser-cutting technology provides a solution for sleek, strong ventilation.

Yes, you absolutely can. By using laser-cutting, ventilation holes can be placed with extreme precision in low-stress areas of the fabric pattern. This method seals the edges of each hole, preventing fraying and maintaining the polo's structural integrity while boosting airflow significantly.

I remember when the only way to add airflow was to sew in a mesh panel. It worked, but it often looked chunky and added extra seams that could chafe. Laser cutting completely changed the game. It allowed us to be more of an engineer than just a sewer.

Precision and Placement

The key is strategy. We don't just randomly punch holes in the fabric. We analyze the polo shirt pattern to find the areas that experience the least amount of stress and the most amount of heat. Common spots include the upper back, under the arms, and along the sides. A laser is programmed to cut tiny, intricate patterns in these specific zones. Because the laser cauterizes—or melts—the edge of the fabric as it cuts, it creates a clean, sealed hole that won't fray or tear.

A Measurable Improvement

We've done tests in our factory, and integrating a well-designed laser-cut pattern can boost airflow by up to 18% in those specific zones. This is not just a marketing claim; it's a real performance enhancement your customers will notice.

| Ventilation Method | Aesthetics | Durability | Breathability Boost |

|---|---|---|---|

| Mesh Panel Inserts | Often bulky; adds seams | Depends on seam quality | Good |

| Laser-Cut Holes | Sleek, modern, integrated | High (sealed edges) | Excellent (targeted) |

| Open-Knit Fabric | Traditional look | Can snag over time | Moderate |

How can "smart fabrics" help you design better polos in the future?

Are you just guessing what your customers want in a performance polo? Guesswork often leads to products that don't sell. Smart fabrics can provide the data to design perfect polos.

Smart fabrics can integrate micro-sensors that track body temperature and sweat levels during a round of golf. This technology provides real-world data, showing exactly where golfers get hottest. You can then use this information to perfect future designs with targeted ventilation and materials.

This is the cutting edge, where apparel design meets data science. Not every polo you produce will have sensors, but using this technology in your research and development (R&D) phase can give you a massive advantage. I see it as building a roadmap for the perfect shirt.

From Guesswork to Data-Driven Design

Traditionally, we rely on general knowledge: people sweat on their backs and under their arms. But is that the full picture for a golfer? The twisting motion of a golf swing creates unique heat patterns. Smart fabric prototypes allow you to collect precise data. You give these prototypes to test golfers and get a "heat map" of their performance. This data tells you exactly where you need a PCM blend or where to put laser-cut holes.

The R&D Feedback Loop

This approach turns product development into a scientific process. It reduces risk and helps ensure your final product is exactly what golfers need. For a new brand, investing in a few smart fabric prototypes for testing can inform your entire product line for years. It shows you're not just following trends; you're creating them.

| Step | Traditional R&D | Smart Fabric R&D |

|---|---|---|

| 1. Ideation | Based on general feedback | Based on general feedback |

| 2. Prototyping | Standard fabric prototype | Smart fabric prototype with sensors |

| 3. Testing | "How does it feel?" | Collects subjective feedback + objective data |

| 4. Final Design | Relies on interpretation | Informed by precise heat/sweat maps |

Conclusion

Fabric choice is everything. By using advanced blends, precise laser-cutting, and smart fabric data, you can create golf polos that offer unmatched breathability and performance for your brand.